Diamond Blade Cutting Depth Chart

However unlike other saws the design of the blade block pistons allows the skid plate to always maintain proper pressure on the concrete ensuring a quality cut.

Diamond blade cutting depth chart. Trailing behind each exposed diamond is a bond tail which helps to support the diamond. Included with every blade is an anti ravel skid plate. The exposed diamond crystals do the grinding work. Cutting depth 4 102mm.

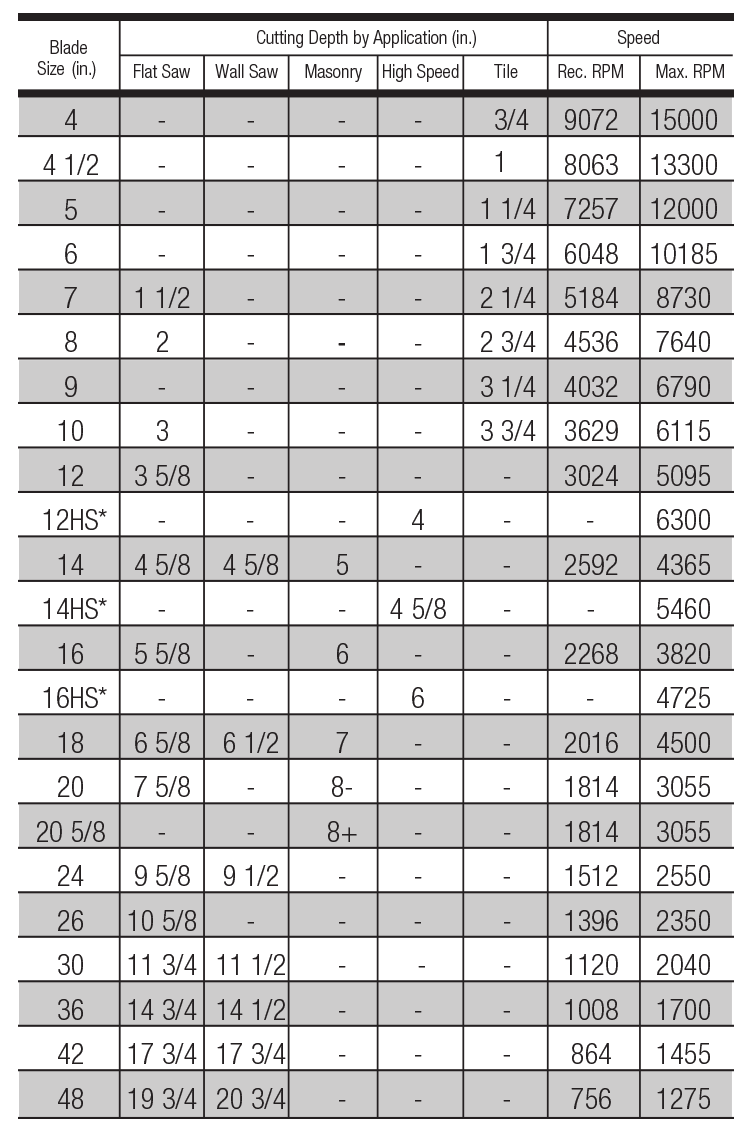

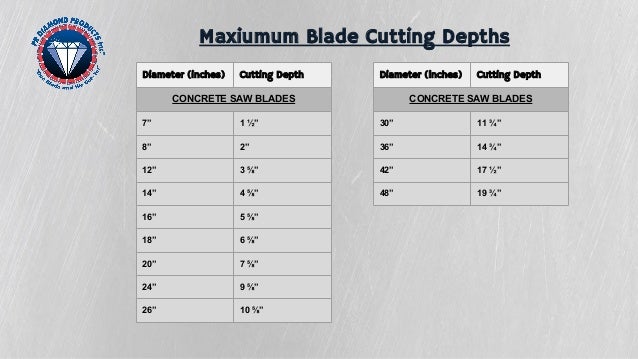

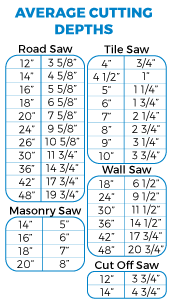

Actual cutting depth will vary with the exact blade diameter or saw type or brand or the exact diameter of the blade flanges. The metal matrix or bond holds the diamonds in place. It is must known thing for all the lapidary artist. Hand held high speed blades.

You must choose between dry or wet cutting. Identify what you will be cutting. Actual cutting depth will vary with the exact blade diameter or saw type or brand or the exact diameter of the blade collars flanges. Ned catalog ned equipment catalog.

Cutting depth will also be reduced if saw components extend below the blade flanges. It is must known thing for all the lapidary artist. For more efficiency of cutting speed and duration you should be sure to select the best type of blade for your application. This chart shows cutting depth for different diamond saw blades.

Cutting depth will also be reduced if saw components motor housing blade guard extend below the blade collars flanges. Diamond blade cutting depths listed above are approximate. This is the single most important factor. As the blade rotates through the material the exposed surface of the diamonds grind the material being cut.

Diamond blade basics specifying diamond blades speed cutting depth chart aggregate map blade troubleshooting. Diamond blades don t cut they grind. Cutting depth may vary depending on saw design. Diamond blade cutting depths listed above are approximate.

Mk diamond products are available through gsa advantage. Cutting depth 6 152mm 2 51mm 7 178mm 2 1 2 64mm 8 203mm 3 76mm 10 254mm 3 3 4 95mm cutting depth may vary depending on saw design. Product specifications subject. The majority of diamond blades cut only a specific variety of materials.

The combination of saw plate and diamond blade enables you to cut on the same day as the. August 26 2013 at 12 28 am. The unique blade block design keeps pressure on the surface of the concrete while the blade cuts. Hand held high speed blades.