Diesel Fire Pump Exhaust Pipe Material

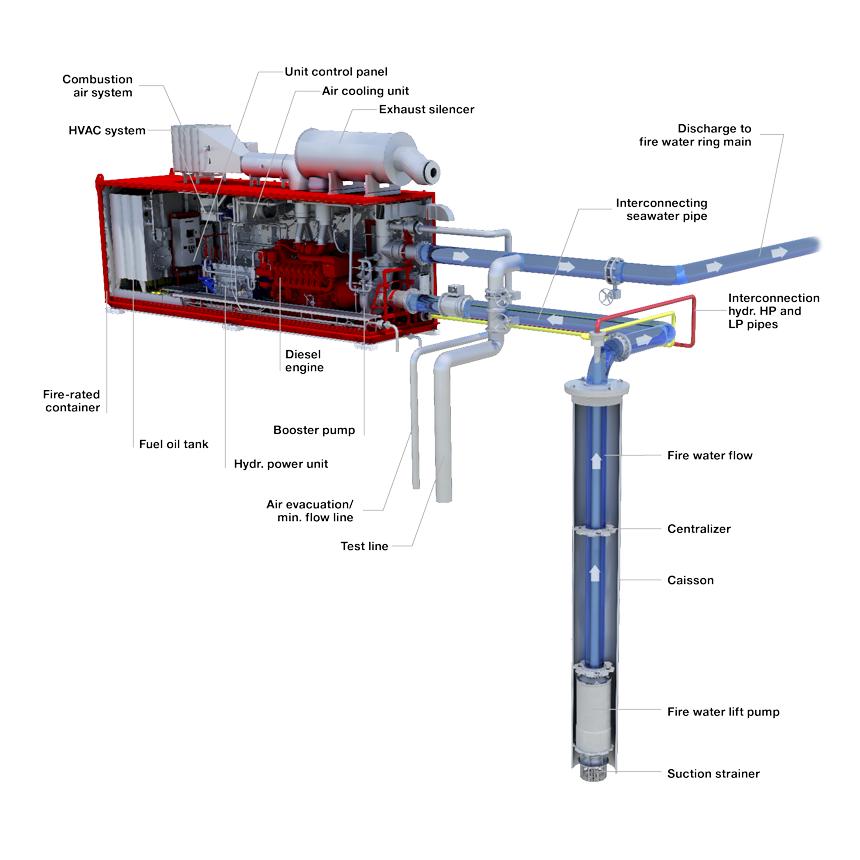

The selection and installation of such suction pipe material is addressed by nfpa 24 which specifies the use of certain types of iron steel concrete plastic and copper.

Diesel fire pump exhaust pipe material. The diesel engine must use clean 2 diesel. Layer of material with a thermal cloth outer layer. Exceeding these limits can cause poor performance fuel pump failure and lack of fire protection. When a diesel generating system is activated it is designed to quickly provide power to pumps blowers elevators and other equipment.

1 blended fuel or jet fuel have a lower cetane ratings which reduces the power output by 10 of the engine compared with the listed power. Due to these high exhaust temperatures some models. Most blankets will be. The high heat put out by the exhaust is a hazard to occupants and can greatly contribute to overheating the room itself.

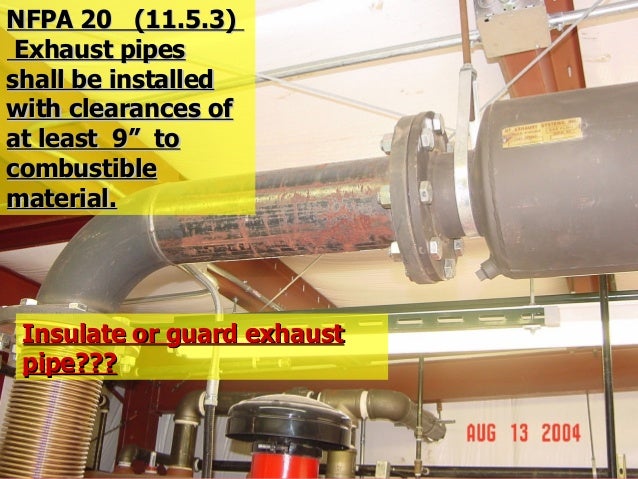

This causes the temperature of the exhaust gases to rapidly change from ambient to 700 f or higher. Some manufacturers state the exhaust temperatures will appr oach 1000 f. The manufacturer states that the exhaust temperature will be about 1100 f. The exhaust from a diesel engine driving a fire pump is an often overlooked item.

The project requires this pump to be on the interior so i need to be concerned with the fire risk of the hot surface. Exhaust pipe insulation 12 water ingress prevention. I need to know what type of insulation and a good idea of how thick to use to insulate the exhaust of a diesel driven fire pump. The i o data for each engine gives a minimum size for supply and return fuel line size.

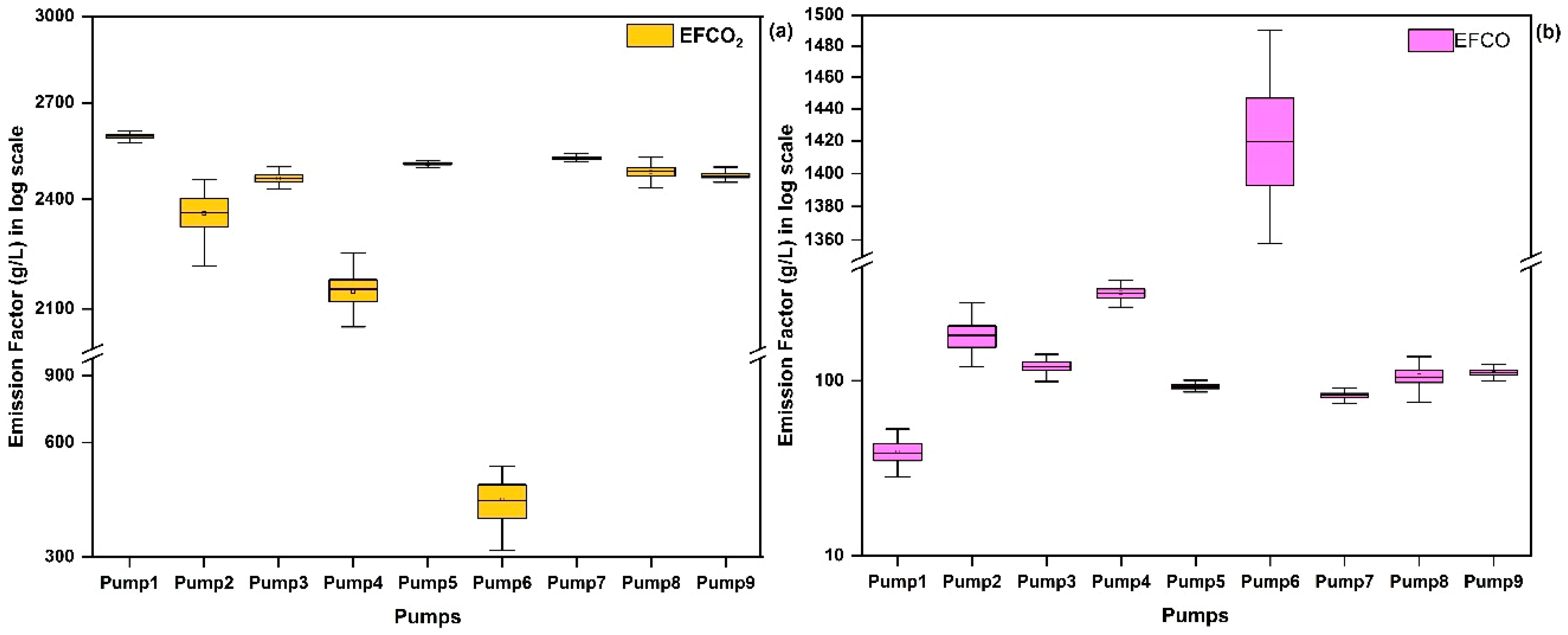

For the purposes of driving a fire pump a diesel engine should run at or near its rated speed so that the fire pump produces the desired flows and pressures. The installation of liquid fueled stationary internal combustion engines and gas turbines including exhaust. Exhaust system 2800 3000 c13414 rev b 3300 3600 based on nominal system. Residual fuels domestic heating furnace oils and drained lubrication oils shall not be used.

A guard pipe protection or approved. Remember do not use galvanized or copper pipe for vent or fill connection pipes on diesel tanks. Minimum exhaust pipe diameter is based on 15 feet of pipe one elbow and a silencer pressure drop no greater than one half the max. Flow analysis must be done to assure adherance to system limitations.

Exhaust temperature compared to diesel engines. Minimum sizes are based on the engine and tank being no more than 10ft 3 3m apart.