Dimple Jacket Heat Transfer Calculations

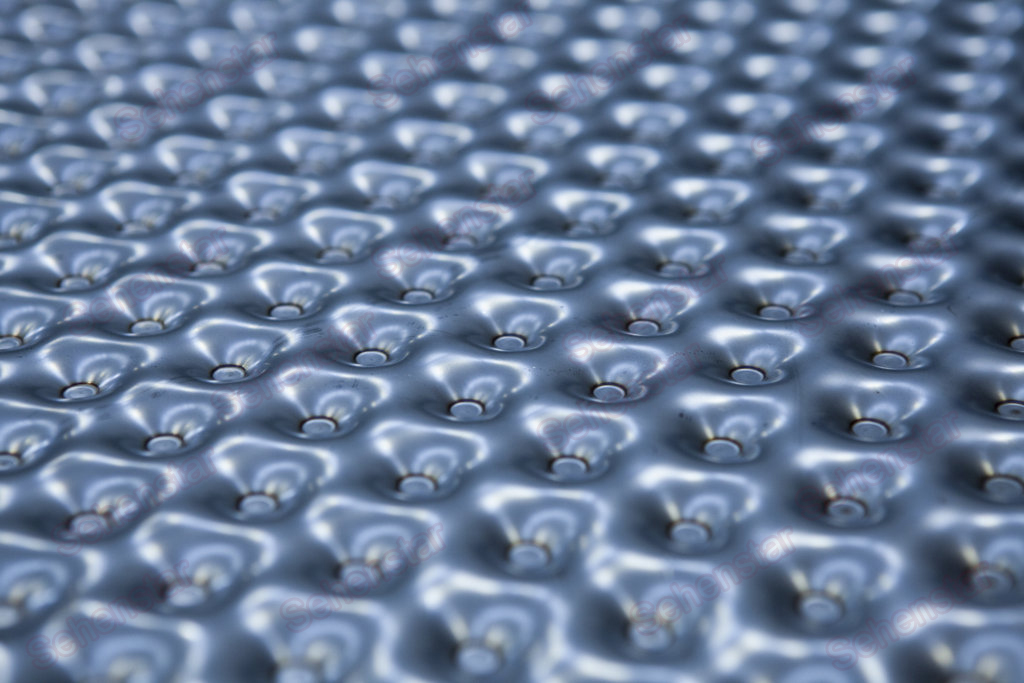

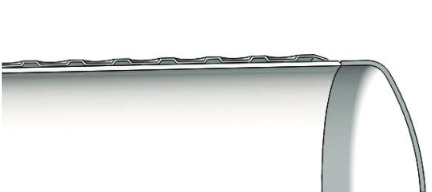

Dimple jackets have far better heat transfer characteristics than conventional jackets due to the turbulence gen erated by the dimples.

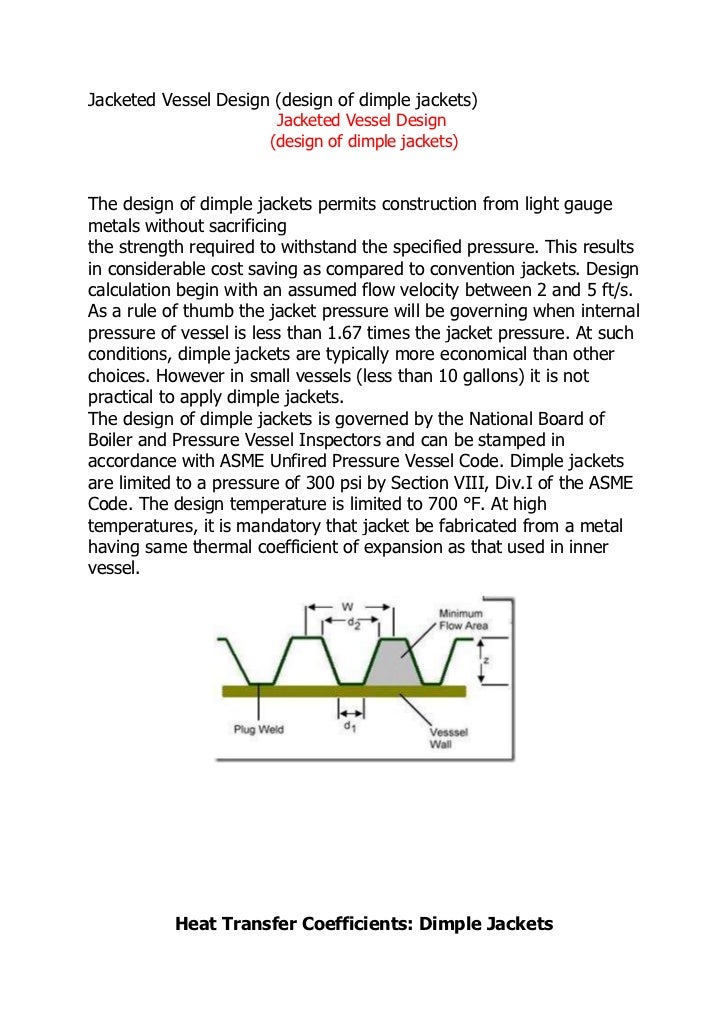

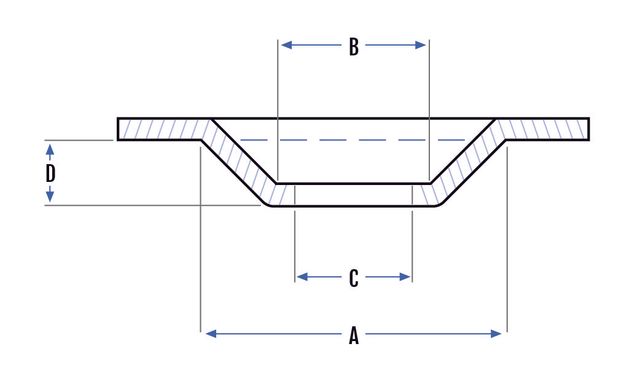

Dimple jacket heat transfer calculations. The dimple jackets are generally limited to 300 psig design pressure while half coil jackets can be used up to a design pressure of 750 psig. Chemical engineering calculations to assist process plant operation and maintenance engineers. Heat transfer can be augment ed by increasing jacket velocities through the use of jacket baffles. Stamped dimple jacket is an efficient heat transfer surfaces for the most diverse range of in tank and on tank applications.

For half pipe coil jacket the higher heat flux rate may require multiple sections of jackets to avoid having condensate covering too much of the heat transfer area. Couple that flexibility with high heat transfer area possibilities and you get a heat transfer surface built for the most rigorous processes. Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with heating cooling medium flowing in jacket spiral jacket or half pipe coil. Vessels can be heated in a number of different ways.

Correlations used to determine the overall heat transfer coefficient and the frictional. Indirect heating of fluids is covered in this tutorial including layouts control and drainage of coils and jackets and heat transfer calculations. This module will deal with indirect heating.