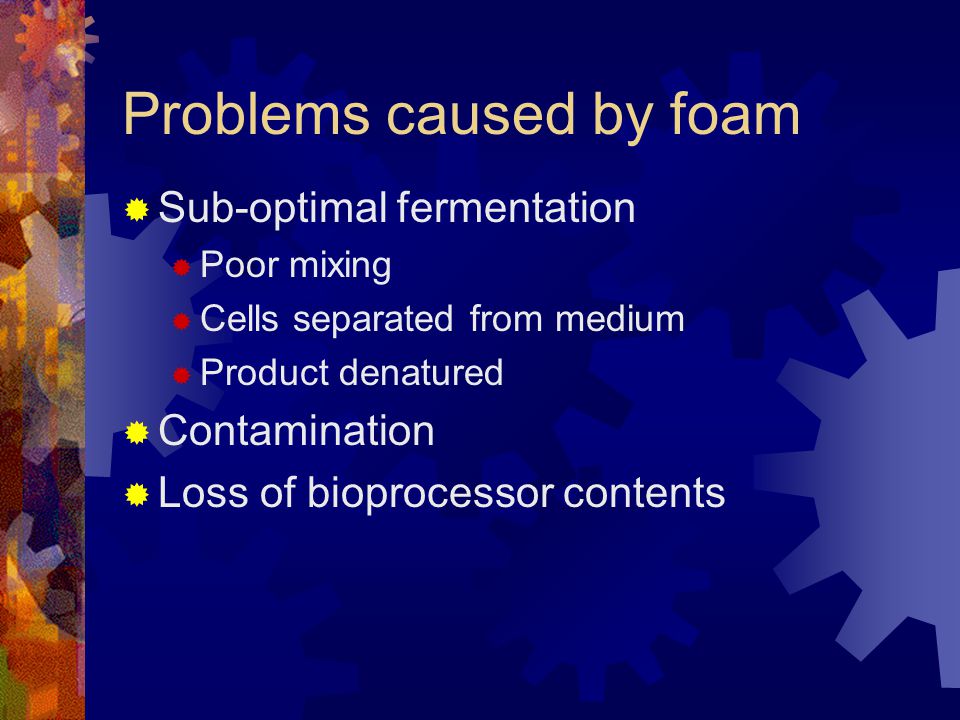

Disadvantages Of Foaming In Fermenter

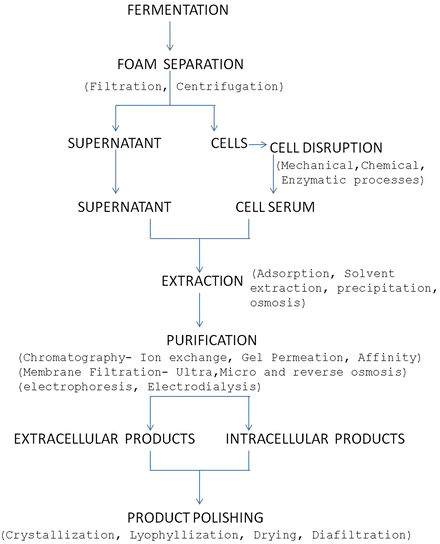

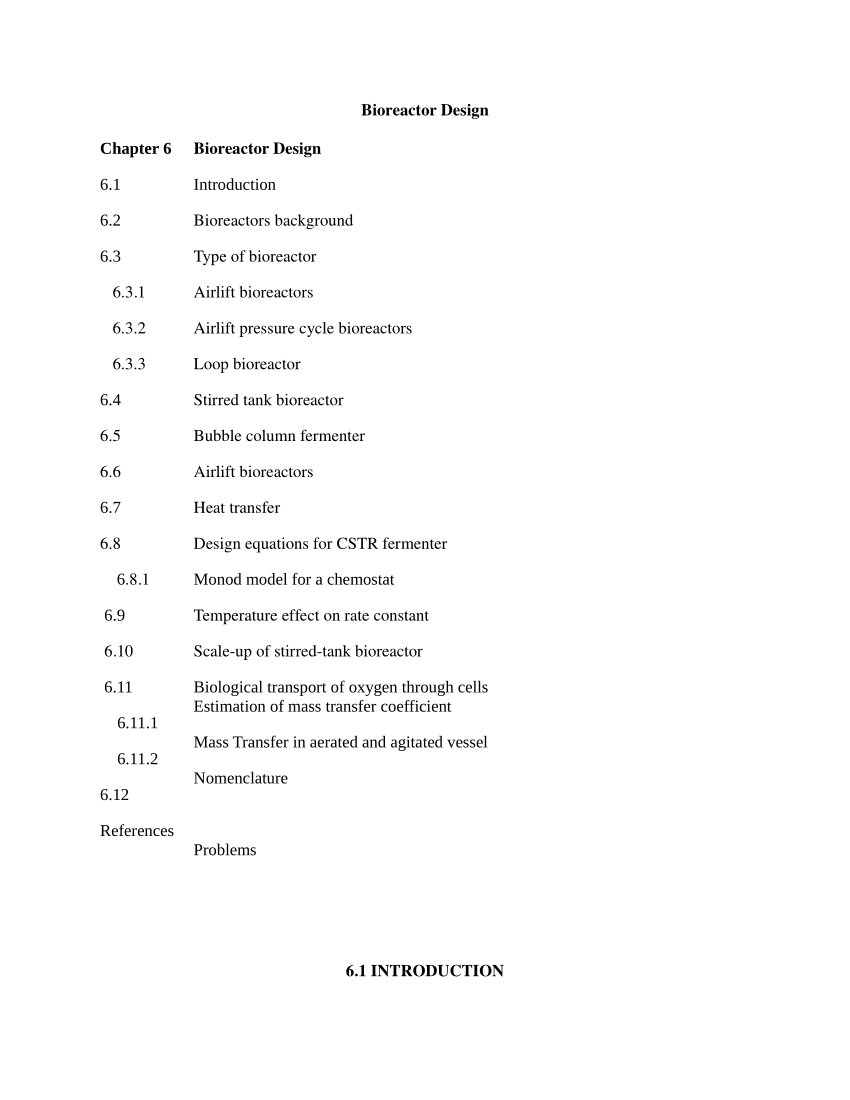

Industrial fermentation is the intentional use of fermentation by microorganisms such as bacteria and fungi as well as eukaryotic cells like cho cells and insect cells to make products useful to humans fermented products have applications as food as well as in general industry.

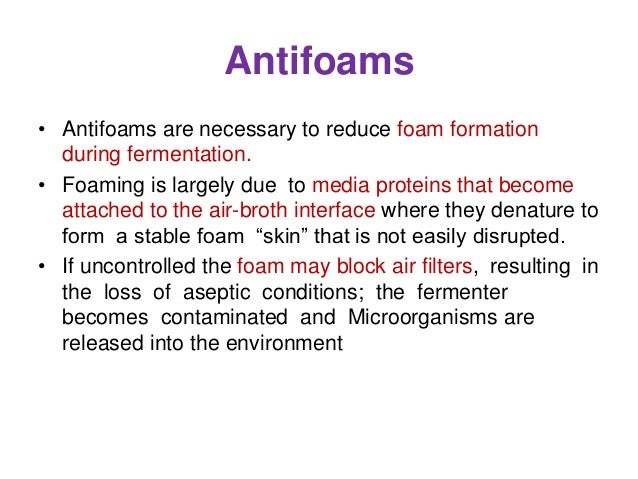

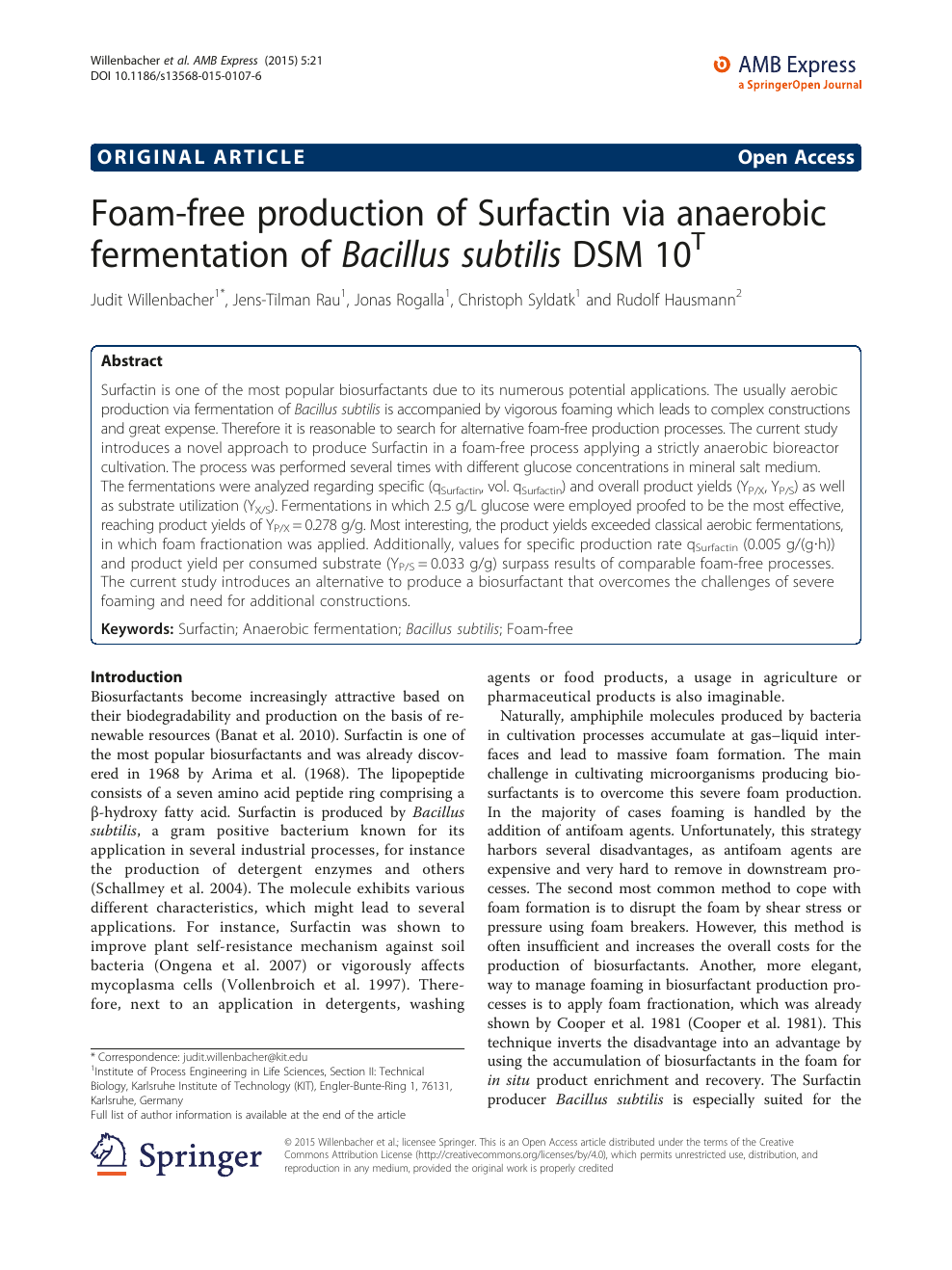

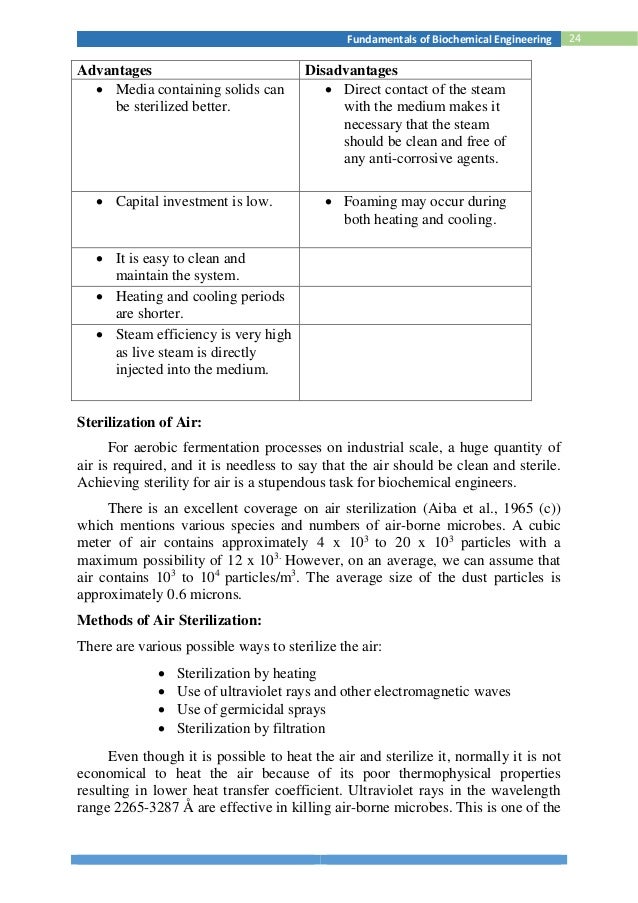

Disadvantages of foaming in fermenter. Foam properties and behavior conditions that affect foaming and consequences of foaming are discussed followed. Overall stainless steel conical fermenters are very easy to use and are a great upgrade to any homebrewery. And if the higher pressure of air needed then more energy consumption needed. We use your linkedin profile and activity data to personalize ads and to show you more relevant ads.

There is a gas flow inlet present at the bottom of the fermentor allows the passage of oxygen. Some commodity chemicals such as acetic acid citric acid and ethanol are made by fermentation. This hollow tube refers to draft tube. It is true that fermented food has some health benefits but there are some disadvantages as well.

Majority of probiotics are found in a group of lactic acid producing bacteria which can be found in fermented milk yogurt and other fermented foods. To adjust the supply air then the higher pressure needed. Many home brew sized conicals have entered the market in the last few years in the sub 200 price range. Cannot use for immobilized cells or enzymes.

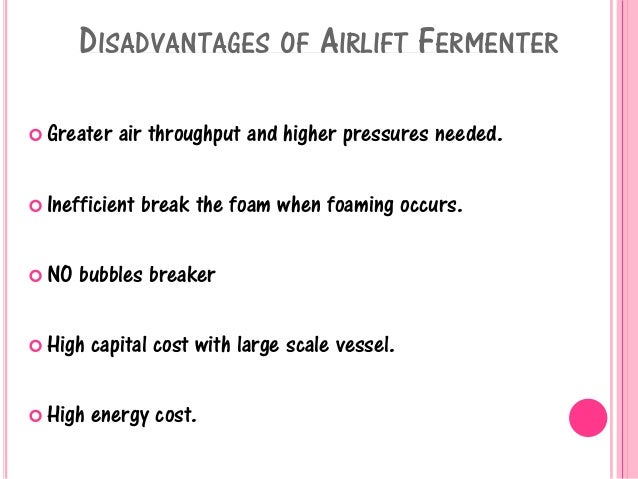

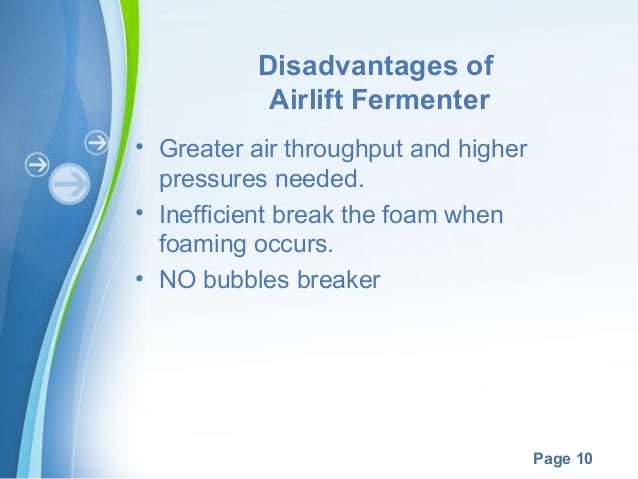

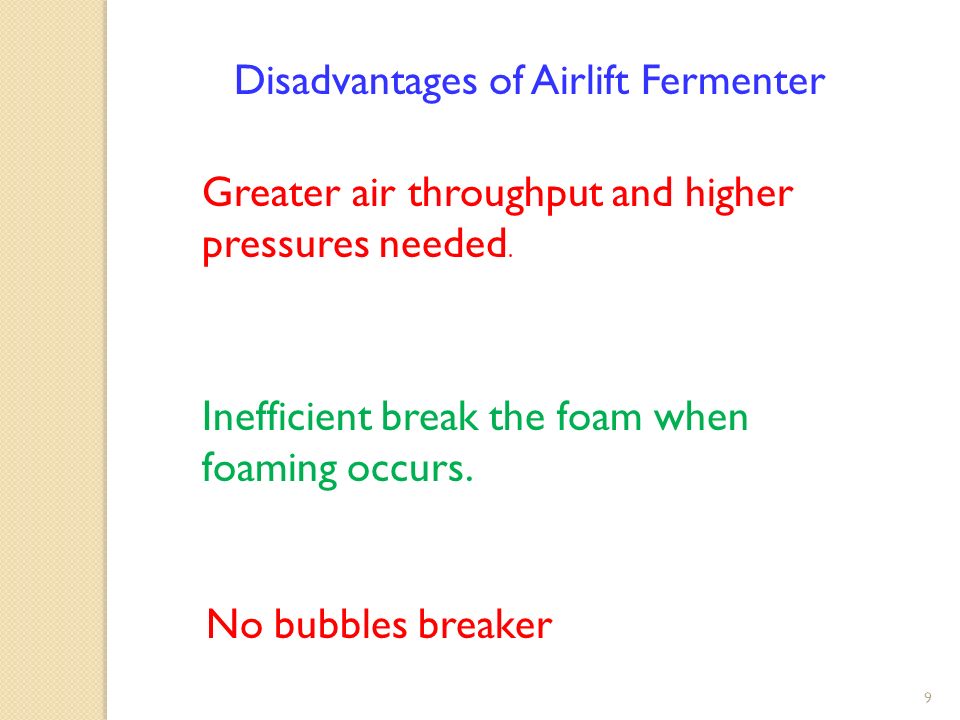

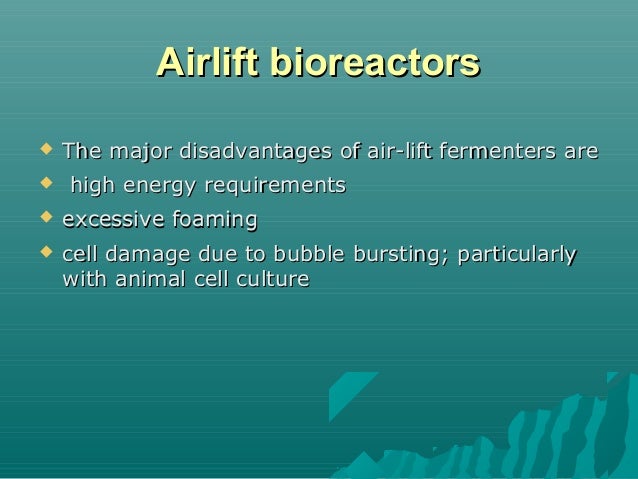

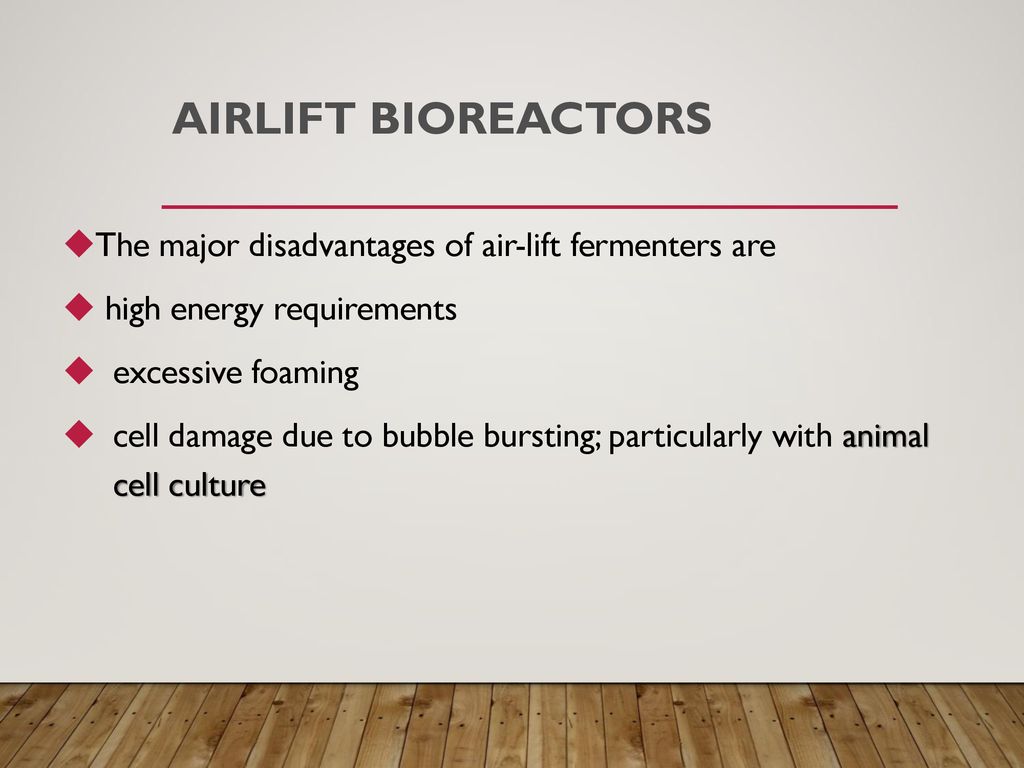

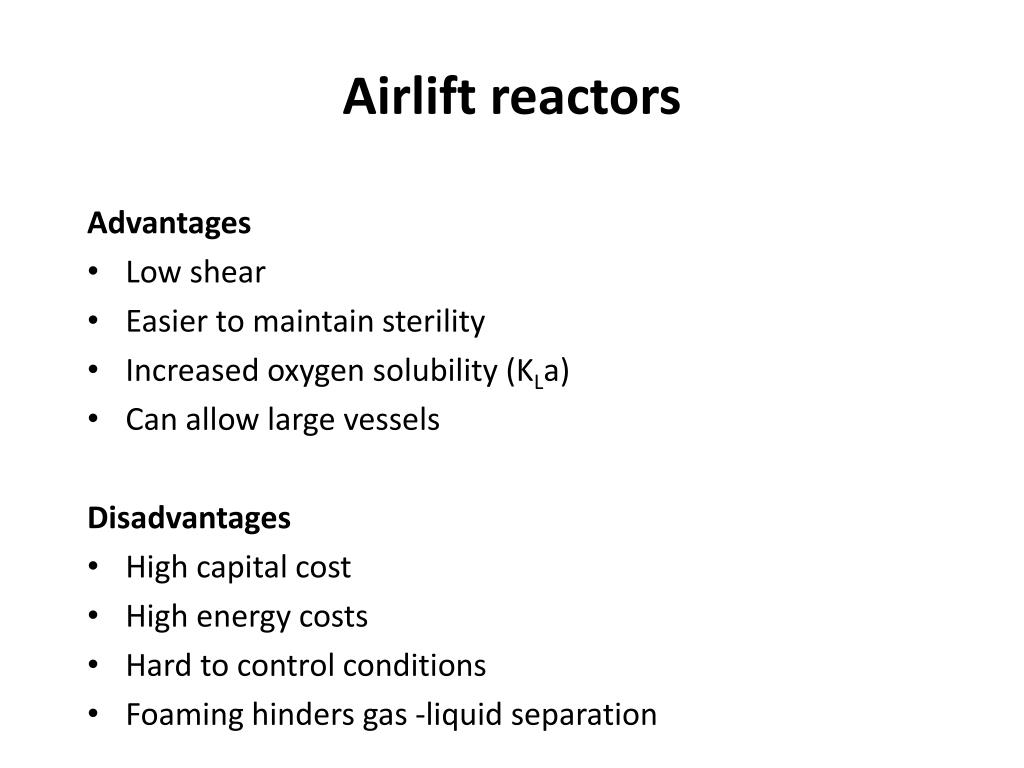

The disadvantages of airlift bioreactor. Greater air throughput and higher pressures needed the agitation on the airlift bioreactor is controlled by the supply air. Industrial fermenters growing cells on a large scale. And more cost must pay.

List of pros of fermentation. Key aspects of foaming and its mitigation in fermentation systems are presented. During my last small batch brew american wheat from northern brewer i came home to find that the foam in the 1 gallon carboy had overflowed the three piece air lock which was a mess to clean out i have read that if it looks like it may bubble over one can use a hose to create an airlock using a bowl of water. It restores proper bacteria balance in intestines.

This racking arm reaches into the center of the fermenter above the level of the trub and sediment and allows clean beer to be pulled and sampled. Known fermenter is used in the production of yeast and has the following disadvantages namely. It consists of a single container inside which a hollow tube is present. I have to say i ve been using primarily carboys for many years but the conical does offer some advantages over a bucket or.

Conical fermenters once out of reach for home brewers have recently become very popular as companies have started making conicals in small and affordable packages.